Frequently Asked Questions

The official Switching Gears for Net Zero Alliance manual, which unpacks the F-gas Regulation and clarifies the meaning of its provisions can be downloaded here:

- Why should we phase out of F-gases in electrical switchgear?

- Are there enough original equipment manufacturers providing alternatives?

- When will the Regulation enter into force?

- What are the new rules for MV and HV electrical switchgear?

- What exactly do the new rules apply to and who is responsible?

- Are there any derogations?

- What about life-cycle assessments?

- What happens if existing equipment needs to be repaired?

- Is the cost of natural origin gas alternatives high compared to F-gas solutions?

- Aren’t F-Gas free alternatives resource-intensive and therefore are not actually more sustainable?

Why should we phase out of F-gases in electrical switchgear?

The race for net zero places clean electricity at the heart of Europe’s energy supply. This shifts the focus to the grid infrastructure itself: it must not harm the environment, the climate, or people.

Switchgears are the ‘nodes’ of power grids. They are essential to ensure that electricity is transmitted and distributed at the proper voltage level.

SF6 stands out as the most potent greenhouse, with a Global Warming Potential (GWP) approximately 24,300 times greater than that of CO2. F-gas based alternatives can also have an elevated GWP.

On the other hand, Natural-Origin Gases (NOG) have zero impact on the climate, the environment and human health.

The revision of the EU F-gas regulation has called for tighter restrictions on F-gases in switchgear. It phases out all F-gases in medium voltage by 2026/2030 and F-gases (GWP ≥ 1) in high-voltage switchgear by 2028/2032. In addition, from 1 January 2035, the use of newly produced SF6 for maintenance or servicing of electrical switchgear is prohibited. This applies to the (re)filling of systems with SF6. Reclaimed or recycled SF6 is exempt from this ban.

Are there enough original equipment manufacturers providing alternatives?

Safe and timely deliveries of NOG technology are ensured. These technologies have already been on the market for 10+ years.

Multiple suppliers can provide NOG in Europe with no patents in place. On the other hand, there is currently only one gas supplier of F-gases for the use in switchgear available.

Over 50% EU market share of medium voltage original equipment manufacturer (OEMs) use NOG technology. 75% of global high voltage OEMs in Europe have NOG technologies available.

The EU F-gas regulation clearly targets F-gas free and GWP consistent with natural origin gases. In response, manufacturers that had previously developed alternative F-gas switchgear are now switching to natural origin gases.

When will the Regulation enter into force?

The Regulation entered into force on 11 March 2024.

What are the new rules for MV and HV electrical switchgear?

01.01.2026: full ban of F-gases in switchgear ≤ 24 kV 01.01.2030: full ban of F-gases in switchgear from 24 kV up to ≤ 52 kV

01.01.2028: ban of F-gases with GWP ≥ 1 in switchgear from 52 kV up to ≤ 145 kV 01.01.2032: ban of F-gases with GWP ≥ 1 in switchgear > 145 kV

What exactly do the new rules apply to and who is responsible?

New electrical switchgear put into operation after dates of ban listed in Article 13.9. The responsibility for compliance lies with the system operators.

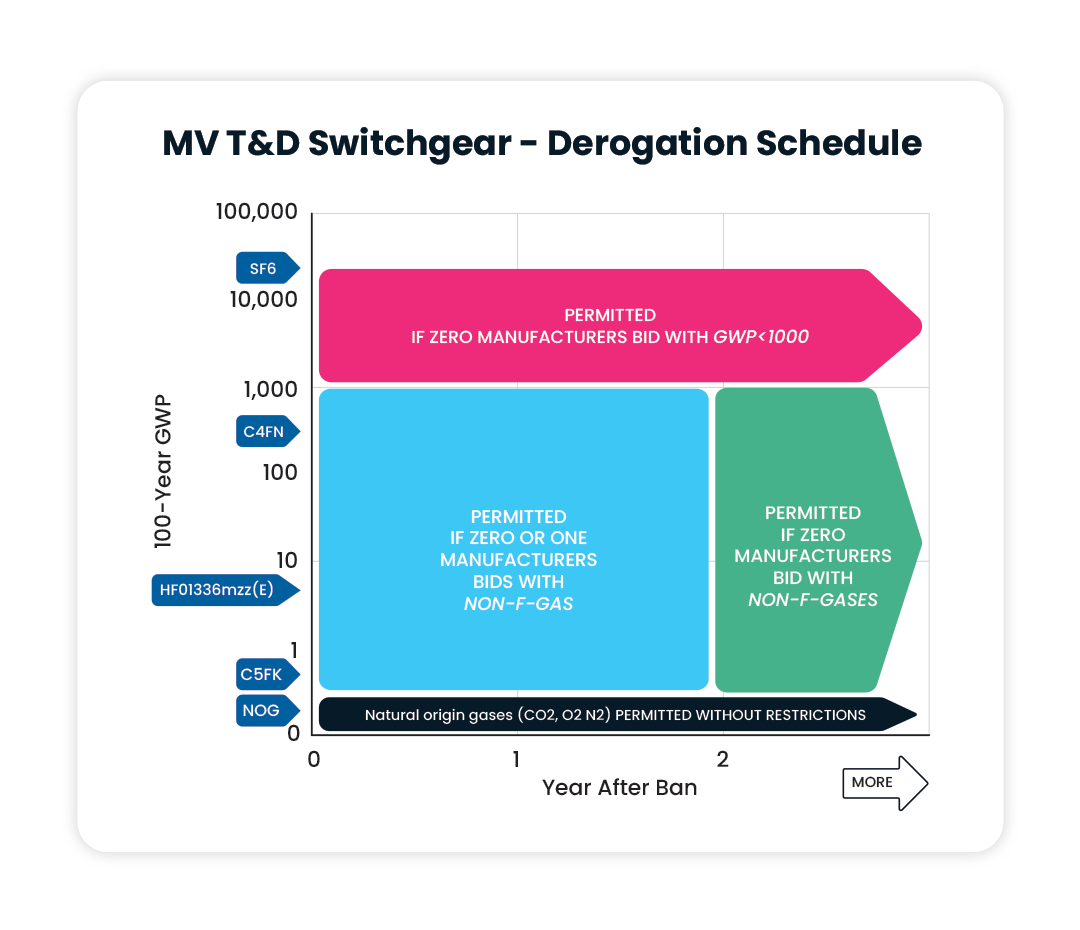

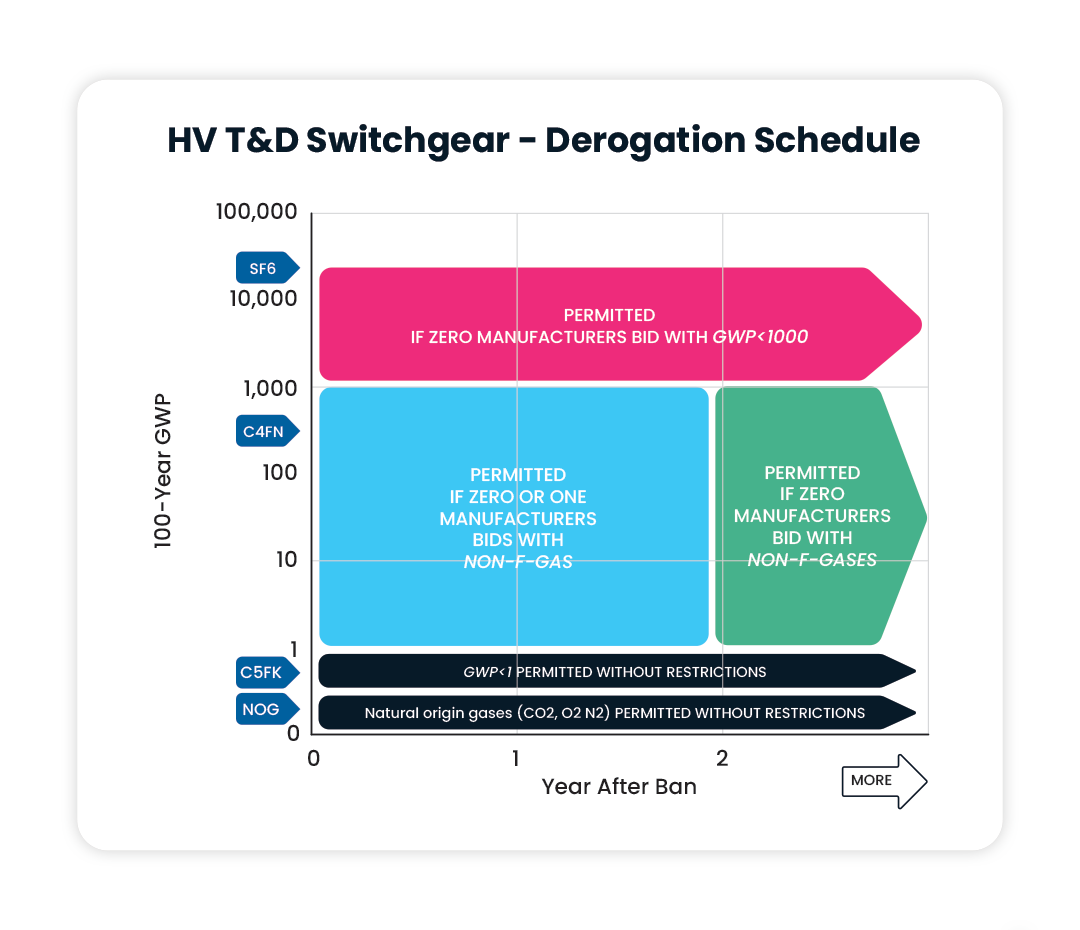

Are there any derogations?

The following scenarios are exempt from the above rules:

- Taking out of operation and putting into operation at a different site is exempt from the rules above, if the equipment was put into operation before entry into force of the Regulation.

- Orders placed before Regulation comes into force

- Repairing and extending switchgear as long as there is no increase in GWP

- The time based derogations below:

What about life-cycle assessments?

The EU F-gas Regulation does give the possibility for exemptions for electrical switchgear for which it has been established pursuant to ecodesign requirements adopted under Directive 2009/125/EC that its life cycle CO2 equivalent emissions would be lower than those of equivalent equipment.

However, currently there are no ecodesign requirements applicable to electrical switchgear under Directive 2009/125/EC nor under the Ecodesign for Sustainable Products Regulation which replaces this Directive. It is currently not foreseeable whether - and if so, when – eco-design requirements will be adopted that enable the proof required for this derogation.

In May 2024, the European Commission confirmed that switchgears are not currently regulated under the Ecodesign Directive and are not included in the current working plan on ecodesign and energy labelling. Therefore, derogations in the regulation based on life-cycle emissions are not applicable to switchgear.

What happens if existing equipment needs to be repaired?

This is allowed for under the EU F-gas Regulation as long there is no increase in GWP.

Is the cost of natural origin gas alternatives high compared to F-gas solutions?

Cost evaluations for carbon neutral switchgear should include CAPEX, OPEX and end-of-life costs, including costs for environment and society. Data shows that natural-origin gas switchgear using NOG as insulating medium may be somewhat more expensive upfront, but that it becomes cheaper than F-Gas alternatives when considering Total Expenditure (TOTEX).

Increased investment cost factors for NOG alternative switchgear can be compensated:

(1) lower insulation capability of NOG insulation without F-gases can be compensated by higher pressure and design modifications;

(2) low sourcing quantities and low production quantities can lead to increased investment costs, but the CAPEX costs will decrease once order, sourcing and production quantities ramp up.

(3) lower gas handling costs over the lifetime.

(4) zero cost of regulatory compliance.

Using F-gases solutions can lead to additional OPEX costs such as: (1) Investing in mixing equipment for refilling and maintenance; (2) Training maintenance team in accordance to EU F-Gas Regulation every 7 years; (3) Reporting; (4) If switchgears are equipped with leakage detection systems, they must be checked at least once every 6 years (Article 6(4)); (5) End of life management of the F-Gas (the release of F-gases is not allowed)

With the usage of natural origin gas, there is no need for special gas handling tools or trainings. Furthermore, it is a secure investment with no follow up cost from F-gas regulation or recycling. This will reduce the life cycle costs significantly.

Aren’t F-Gas free alternatives resource-intensive and therefore are not actually more sustainable?

Companies in the sector have developed solutions to optimise the resource-intensity of natural origin gas switchgear. While natural origin gases might have lower inherent electrical insulation performance, this can be compensated by higher pressure or innovative design features, such as low-power current and voltage transformers.

Decarbonised materials and circular economy measures in high voltage switchgear lead to reduction in CO2 emissions through material optimisation and recycling, contributing to a more sustainable and environmentally friendly production process.

In addition, the EU taxonomy, which guides investment in environmentally sustainable activities, specifies that switchgear relying on F-gases with a GWP greater than 10 are not considered compliant with its sustainability criteria. This further emphasises the benefits of choosing natural-origin gas alternatives.